Aluminum Department

Trellidor is a pioneer in the aluminum industry in Israel for home and yard enclosure products – gates, fences, pergolas, screens, cladding, and more. As part of this, Trellidor operates the country’s largest and most advanced manufacturing system in this field. The aluminum division is located in Plant No. 2 within the group’s complex in Carmiel. It comprises departments that develop practical, high-quality, and advanced products tailored to customer requirements using the Taylor Made method.

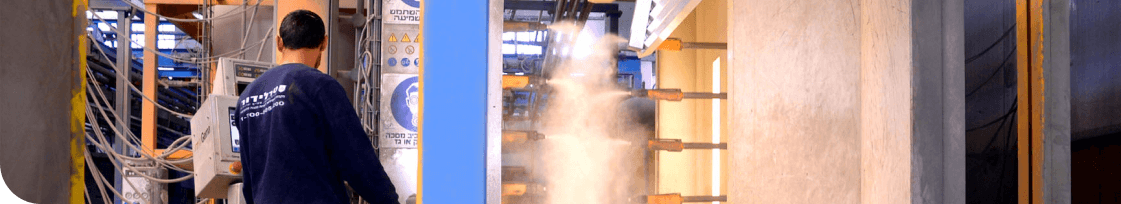

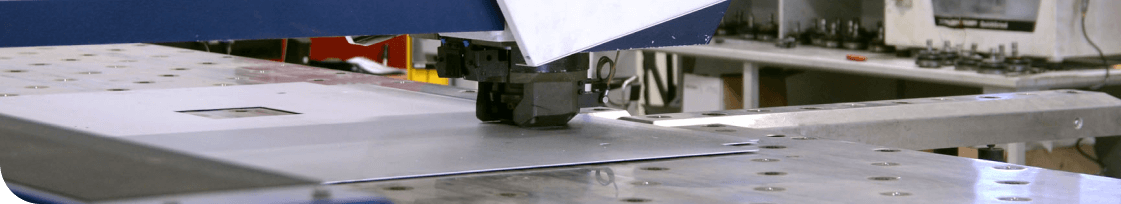

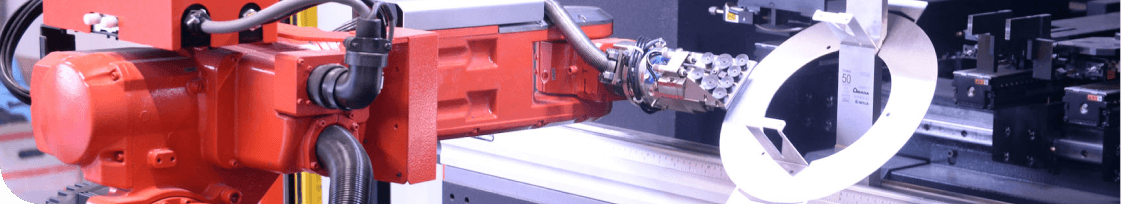

The production process at Trellidor is diverse and includes multiple departments involved in creating high-quality, aesthetic, and durable products. To achieve this, advanced systems are employed, placing Trellidor at the forefront of industrial technology, including laser welding machines, robotics, automated bending systems, laser profile cutting machines, and more. This advanced machinery allows the production of over 3000 different products every day.

Following engineering, the aluminum division of Trellidor is comprised of several central departments: cutting, welding, polishing, painting, and packaging. Manufacturing employees in these departments receive regular professional training, enabling them to facilitate new production processes, as their vast knowledge and expertise mainly revolve around aluminum.

Trellidor takes great pride in manufacturing products of the highest quality and finishing in the market. For this purpose, a quality control system oversees the processes from procurement to packaging before sending the products to customers.

Another department within Trellidor’s aluminum division is the development department, which continuously examines market demands for new products and innovations, leading to stunning designs alongside technical solutions that provide every customer with the most comprehensive and best possible solutions, positioning Trellidor as a market leader in its field.

Higher Quality Aluminum:

Aluminum is a lightweight metallic material with a 2.7 g/cm³ density.

It is known for its high resistance to corrosion (unlike iron) and is, therefore, most suitable for industries such as construction, chemistry, electronics, textiles, and food.

Good reflectivity of light and heat.

Can be processed plastically into any shape.

When exposed to the atmosphere, aluminum forms a thin and invisible layer of aluminum oxide (Al₂O₃), which prevents further oxidation and protects the profile from corrosion.

The material undergoes an aging process – Aluminum Anodizing.

All Trellidor products are made from superior aluminum sourced only from leading companies: klil and Alumicco (Greece).

AGING PROCESS | Aluminum Anodizing:

Anodizing is a thermal treatment method designed to strengthen and harden materials such as aluminum, magnesium, and titanium.

Many companies do not invest in high-quality aluminum and do not perform maximum anodizing.

All raw materials and profiles entering Trellidor’s inventory undergo the maximum anodizing.

Many companies purchase raw materials that have undergone anodizing (hardening) to approximately three times their natural strength. Trellidor processes its raw materials for most products with an anodizing process that increases their natural strength about four times – the maximum anodizing process.

Security Division

Trellidor Company was established in 1991 and has been considered a leading company in Israel in home and business security ever since. In various types and designs, Trellidor offers different bars – fixed, folding, transparent, and more. Their prominent advantage is that they are manufactured with innovative methods, without welding points, ensuring the durability and appearance of the bars over the years. Over time, Trellidor has become a household name in the security industry, and the company’s products can be found in every home in Israel.

Trellidor’s folding bar is a top-rated flagship product that meets a dual need – protection against intruders from the outside and the option of emergency evacuation from the inside. Additionally, many architects have embraced folding bars as an optimal solution due to the winning combination of maximum security and perfect design. The bars are made of steel, undergoing surface treatment to prevent rust, a reinforcement process, and electrostatic painting in an oven – no wonder customers claim that the product maintains its durability for over thirty years. The locking system was specially developed for Trellidor’s bars: a 5-pin cylinder that operates a bolt system locking into the mushroom caps installed on the locking strip; a turn of the key causes the bar to lock by connecting the bolt and the locking strip – locking at two points. The mechanism is a registered and patented design with the number 8418222.

With us, you can provide your children with absolute security in preventing falls from high places while enjoying an uninterrupted view from the window. The transparent bar is an exclusive product of Trellidor. The bar is made of polycarbonate slats with polished edges for maximum safety and a thickness of 10 mm, complying with the ASTM-F2002-00 standard.

The transparent bar has a unique cover for the hooking profile designed to conceal the hooking screws and create an aesthetic look along the wall. The transparent bar is simple, easy to clean and maintain, highly durable, and provides complete peace of mind. Trellidor’s railing heights offer a complementary solution to our children’s need for safety and protection. The standard railing height on balconies in a high-rise building is 1100 mm. Since balconies mainly serve as an additional activity area for children and families, there is a real risk that children will grasp objects and pose a fall hazard. Therefore, we have developed a line of additional railing products with a height of approximately 300 mm on top of the existing railing to prevent falls, focusing on children.

Engineering Department

The department that makes the difference for you – the engineering department

The department that makes the difference for you – the engineering department. This department includes skilled professionals who are engaged in the planning and developing of thousands of products within the Trellidor group and work at all times to design the most stylish, durable, and high-quality products for you. The department works with specially developed planning and engineering systems for Trellidor, with access to extensive engineering databases accumulated over many years of experience. These databases include, among other things, simulations, and drawings that enable maximum speed in the production process, finding ideal solutions for on-site challenges, and all done with flexibility, creativity, professionalism, and full consideration of customer needs.

Advantages of the Department

Approvals – Handling all the necessary approvals for each product in the project. Approvals from the Institute of Standards and approvals by contractors.

Customized product development and engineering – Trellidor’s engineering department oversees the best planning for 3000 products manufactured daily in the group’s factories.

Simulations – Creating simple and complex simulations for all projects and products already in the initial planning stage.

Shop-Drawings – Detailed part breakdown of each product according to engineering requirements to achieve complete transparency and engineering understanding.

The engineering department liaises with all relevant external bodies, construction and planning companies, providing personal and collaborative guidance.

The engineering department implements new manufacturing processes and advanced technologies to establish Trellidor as a leader in its field.

Employing the best professionals in their fields, with a rich experience of many years combined.

Paint Department

Trellidor has an advanced paint department specially developed to offer customers the broadest range of colors, uncompromising quality, and maximum speed.

GS2 | Double-sided galvanizing to prevent corrosion (chemical preparation process before painting)

All metal parts, profiles, and castings (aluminum and iron) undergo a chemical preparation process as soon as they enter the company’s factories.

This process is designed to create advanced preparation for electrostatic painting, similar to the automotive industry, where products must withstand varying weather conditions (strong sunlight, rain, etc.) and require thorough preparation. Without this preparation, the paint will not hold up and will peel, and the product will immediately begin corrosion.

At Trellidor, we do not compromise on the physical preparation process – it is applied to all our products.

REACH | Non-toxic painting adapted to European standards

All Trellidor products are painted exclusively with electrostatic powder coating and then undergo a curing process in an oven.

Trellidor has a professional painting system with 2 Swiss-made ovens operating around the clock.

Unlike other companies, all painting work is carried out at Trellidor’s factories under strict quality supervision, and we do not outsource painting to external facilities.

All paint powders used by the company comply with Israeli standards and are of high-quality Israeli origin.

Trellidor’s paints are non-toxic and do not contain lead.

Glass Division

The Terllidor company has a factory for processing and cutting glass with all the mechanization required to produce various types of railings and protection solutions in large quantities.

In 2016, Trellidor decided to open the factory due to a steady increase in demand for glass railings alongside aluminum and the integration of glass in Trellidor products such as gates and fences. Additionally, to reduce downtime, Trellidor is now the only company in the country where the entire railing production process occurs in one location without external suppliers.

Due to its diverse capabilities and products, the glass division’s production line caters to the needs of contractors, architects, and private customers. As part of this, there are various glass thicknesses, different types of glass, unique shades, and even black glass. The comprehensive production line includes all necessary stages, from cutting and drilling to polishing and delivery, all tailored to the customer’s requirements.

Panel doors Division

Trellidor’s panel gates division operates as a genuine factory and is the largest department in Israel for manufacturing domestic and open parking panel gates.

Trellidor’s panel gates offer numerous advantages, including entrance sealing with rubber and a unique spring system to ensure its durability and maximum safety during operation. Another significant advantage of the panel gate is its upward roll without protruding to the street or beyond the boundary line, thus not obstructing the sidewalk and endangering pedestrians. Additionally, Trellidor’s panel gates are powered by Italian motors, known as the best and most durable in the industry, exclusively paired with the world’s top companies. By incorporating the subsidiary company “Eltron,” specializing in manufacturing complex and well-known gates and panel doors in upscale neighborhoods in Israel, the united panel division has become the leading department in Israel regarding production methods and product variety.

Panel gates come in four colors: white, cream, light gray, and dark gray. However, additional colors can be ordered, especially when there is a need to match the gate’s appearance with the rest of the house facade (fence, pedestrian gate, etc.). Trellidor’s panel gates come in the broadest range of designs according to customer requirements and Trellidor’s product line: high-tech models, profiles, glass-integrated designs, and more.